Pharmacode Reader

Color Code and Print-to-cut Solution

Leary’s Pharmacode reader and quality assurance system will protect against mixed copy, check for the absence and presence of color, measure print-to-cut registration in both the in-line direction and the cross machine direction. The scanner will read expanded Pharmacode at 900 m/min with print-to-cut accuracy of up to (+/-) .1 mm (.004 in).

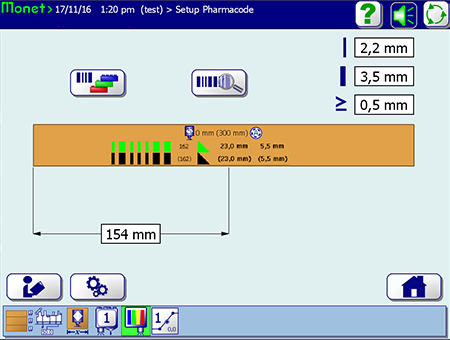

The color bar sequence and print-to-cut values are master learned with the touch of a button or they may be manually entered. Our MaQ+ and Array controllers, when integrated, allow you to see real-time passed or failed code values.

The Pharmacode / Print-to-Cut solution is available in three bracket configurations. One option is suitable for applications where space is limited. The second option is specific to a Bobst gluer and the third option is a sword style guide which replaces the pre-break device on your gluer.

- Mixed copy detection

- Absence and presence of color

- Expanded (1-2-3) Pharmacode detection up to 900 m/min.

- True Pharmacode (0-1-2) up to 450 m/min

- Measures print-to-cut, cut length and cross length

- Print-to-cut accuracy of up to (+/-) .1mm (.004 in) at 600 m/min

- High speed RGB LED sensor for accurate color detection

- Bar sequence and print-to-cut values may be learned or manually entered

- Real-time display of scanned Pharmacodes

- Available in three configurations based on gluer

Software Overview

Dynamically scaled graphics allow the operator to see the exact locations of applied glue and detected barcodes or other QA inspection. Verifying correct position on the screen first, ensures proper setup without waste. Defective products are rejected with a variety of efficient removal or marking systems.

Resources

Solutions For Your Industry

Leary solutions are offered to improve plant efficiencies, decrease setup time, increase uptime and lower product waste, regardless of machine type.