Other Detection Options

Leary offers the widest range of detection solutions for producing 100% quality product and improving the carton making process.

Window Detection

Leary’s Window (Cello) detection station works in conjunction with all MaQ+ and Array controllers to ensure the cellophane window covers the entire cut-out area on the carton. This sensor detects for presence and/or placement of cello to determine if there are any variations such as missing, misplaced, or skewed window detection.

Sensor options include basic absence/presence, detecting for the start and end position of the cut cello with 1 sensor, or using 2 sensors to detect any skew and verify alignment of the cut cello.

- Window / Cello detection at 650 m/min (2,150 ft/min)

- Detect for presence and/or placement of cello

- Option to detect for skew and side to side placement

- Detect cello on white or colored board

- Can detect printed cello (glare type)

- Machine specific mounting

Double Carton Detection

Double carton detection prevents unglued or misfolded cartons and machine jams due to double-fed cartons. Measure board thickness with option to shut down the machine or reject cartons to reduce waste.

- Non-contact, ultrasonic Sensor

- Bracket with sensor and built-in trigger for fast make-readies

- For use with all solid board materials

- 24 pt caliper board

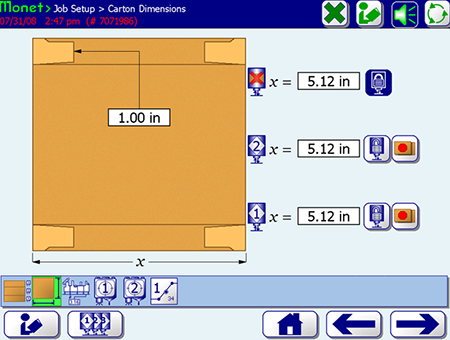

- Simple Monet setup

Skew Detection

Detect skewed cartons from the feed or turning section by monitoring left and right-side skew and register shifts. Properly aligned cartons ensure accurate gluing placement and folding for 100% fit-for use cartons.

- Choose from one sided, two sided & leaded edge

- Detect the exact amount of skew error, providing appropriate actions including glue inhibit

- Determine skew pass point values from Monet OS

Flaps Detection

Flaps detection monitors the entire length of the panel to ensure leading and training edges are undamaged. Ensure all flaps are intact and the absence/presence of cutouts. Reject or shut down the machine for faulty cartons.

- Choose from up to 4 panels to measure the length of the product

- LED output for visual verification

- Flap detection panel in Monet for on-screen visual verification of settings

Software Overview

Monet software is equipped with SureScan Technology to ensure that each quality control station is functioning as intended. Cartons are tracked through the full length of the machine from feed to packing, building checkpoints of passing through each station. If a product is not monitored by any station, that product will be rejected.

Solutions For Your Industry

Leary solutions are offered to improve plant efficiencies, decrease setup time, increase uptime and lower product waste, regardless of machine type.